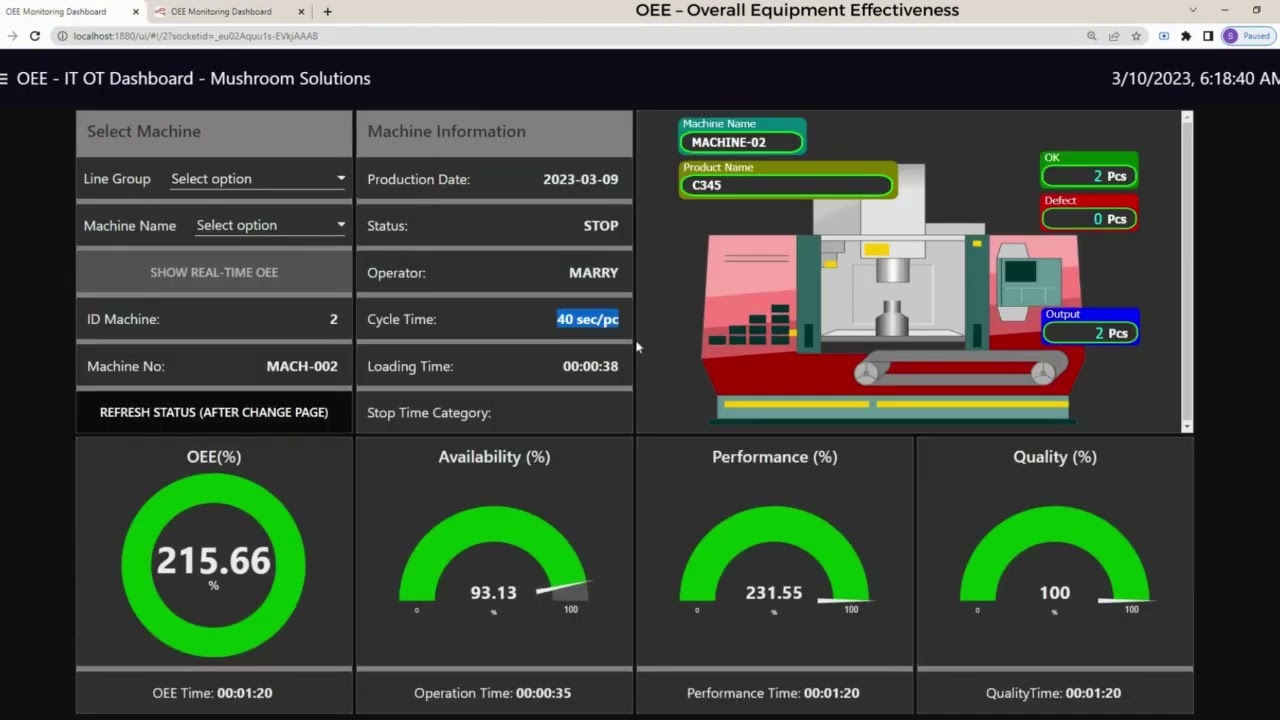

OEE – Overall Equipment Effectiveness

Mushroom Solution’s extensive service for Overall Equipment Effectiveness (OEE) Analysis empowers you to uncover how our specialized knowledge can assist you in unleashing the complete potential of your operations. Through this analysis, we aim to enhance efficiency and optimize manufacturing productivity, providing you with valuable insights to drive operational excellence.

Our OEE Offerings

Performance Evaluation

Gain insights into your equipment's performance by analyzing key metrics such as availability, performance rate, and quality rate. Identify bottlenecks and areas for improvement to streamline your processes.

Downtime Analysis

Pinpoint the reasons behind equipment downtime, whether they are due to mechanical failures, changeovers, or maintenance. Our analysis helps you minimize downtime and optimize scheduling.

Quality Assessment

Evaluate the quality of your output by analyzing defects, rejects, and rework. Our OEE analysis aids in identifying root causes and implementing measures to enhance product quality.

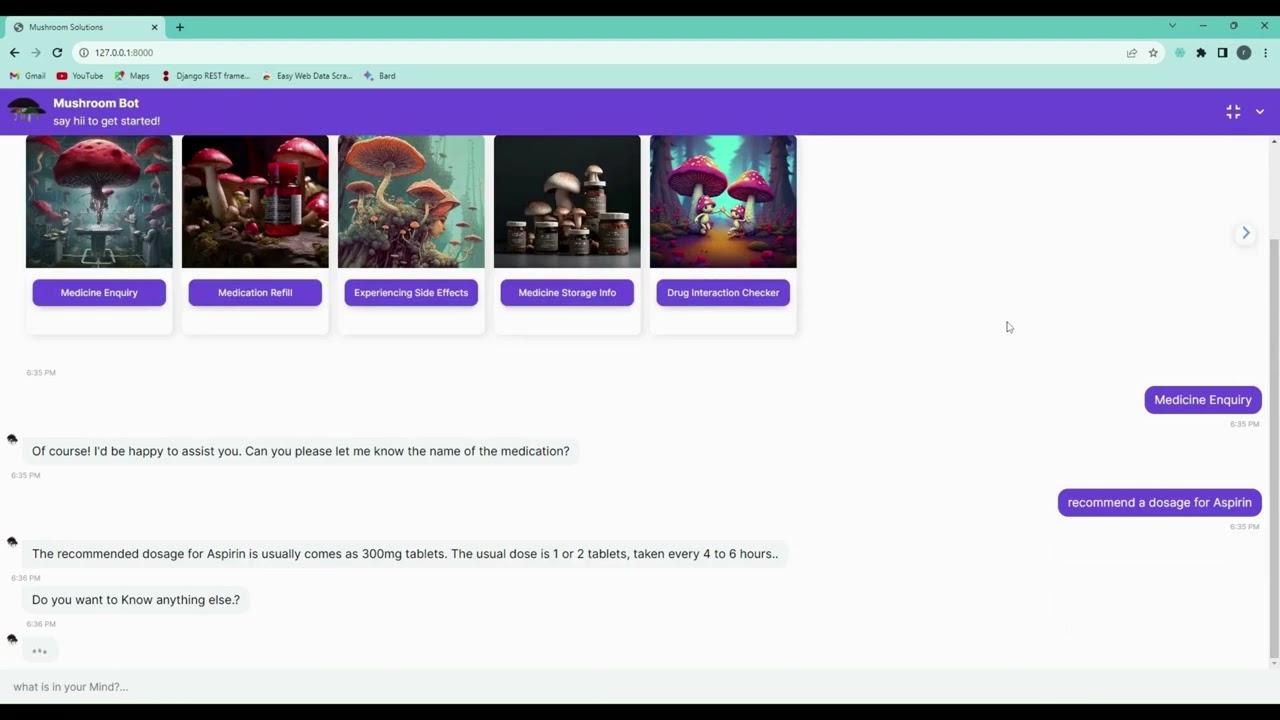

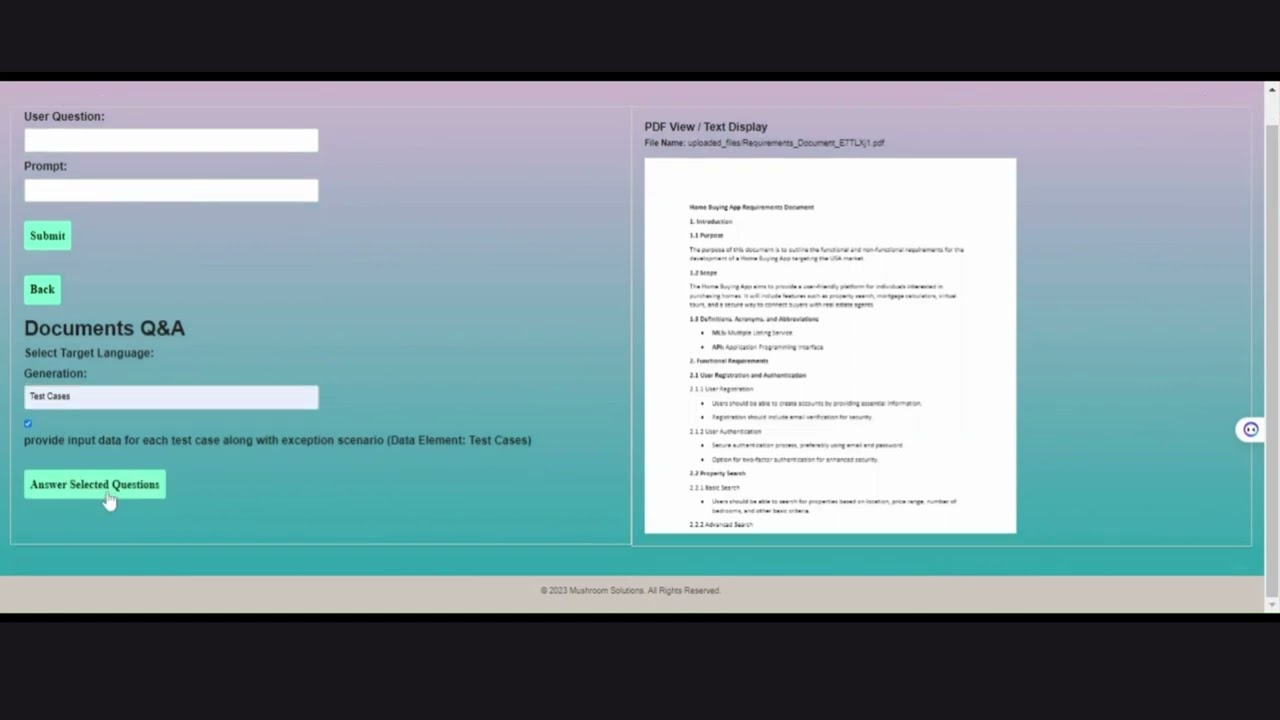

Data-Driven Insights

Harness the power of data by implementing advanced analytics and visualization tools. We provide you with real-time dashboards and reports that offer actionable insights for data-driven decision-making.

Benefits of OEE Analysis

Increased Efficiency

By identifying and addressing equipment inefficiencies, you can reduce production losses, leading to higher overall efficiency and output.

Optimized Production

With a clear understanding of your equipment's performance, you can fine-tune production processes, resulting in reduced lead times and improved on-time delivery.

Enhanced Quality

Our analysis helps you detect and rectify quality issues early, leading to fewer defects and improved customer satisfaction.

Resource Optimization

Efficient equipment utilization reduces energy consumption and minimizes maintenance costs, leading to better resource allocation.

Continuous Improvement

OEE analysis provides a baseline for measuring improvements over time, fostering a culture of continuous enhancement within your organization.

Our OEE Approach

Data Collection

Metric Calculation

Root Cause Analysis

Actionable Insights

Implementation Support

Why Choose Us

Expertise

Our team comprises seasoned professionals with extensive experience in OEE analysis across diverse industries.

Custom Solutions

We tailor our approach to your specific operational needs, ensuring that our analysis aligns with your business goals.

Proven Results

Our track record speaks for itself – we've helped numerous clients achieve substantial improvements in their equipment effectiveness.

Collaborative Approach

We work closely with your team, combining your operational insights with our technical expertise to achieve optimal results.

Enter details to access demo

Please enter your details before accessing demo

Unlock the potential of your operations with our OEE Analysis service with Mushroom solutions.

Our Solutions Gallery

Elevate your manufacturing operations with Mushroom Solutions' OEE Analysis. Our comprehensive approach optimizes efficiency, reduces downtime, and enhances product quality. Unleash the power of data-driven decision-making, resource optimization, and continuous improvement. Transform your manufacturing landscape with Mushroom Solutions - where operational excellence is not just a goal; it's a guarantee.

Liked the demo?

Reaching out to Mushroom Solutions can provide customers with the opportunity to leverage cutting-edge technology, receive expert guidance, and achieve their business goals.